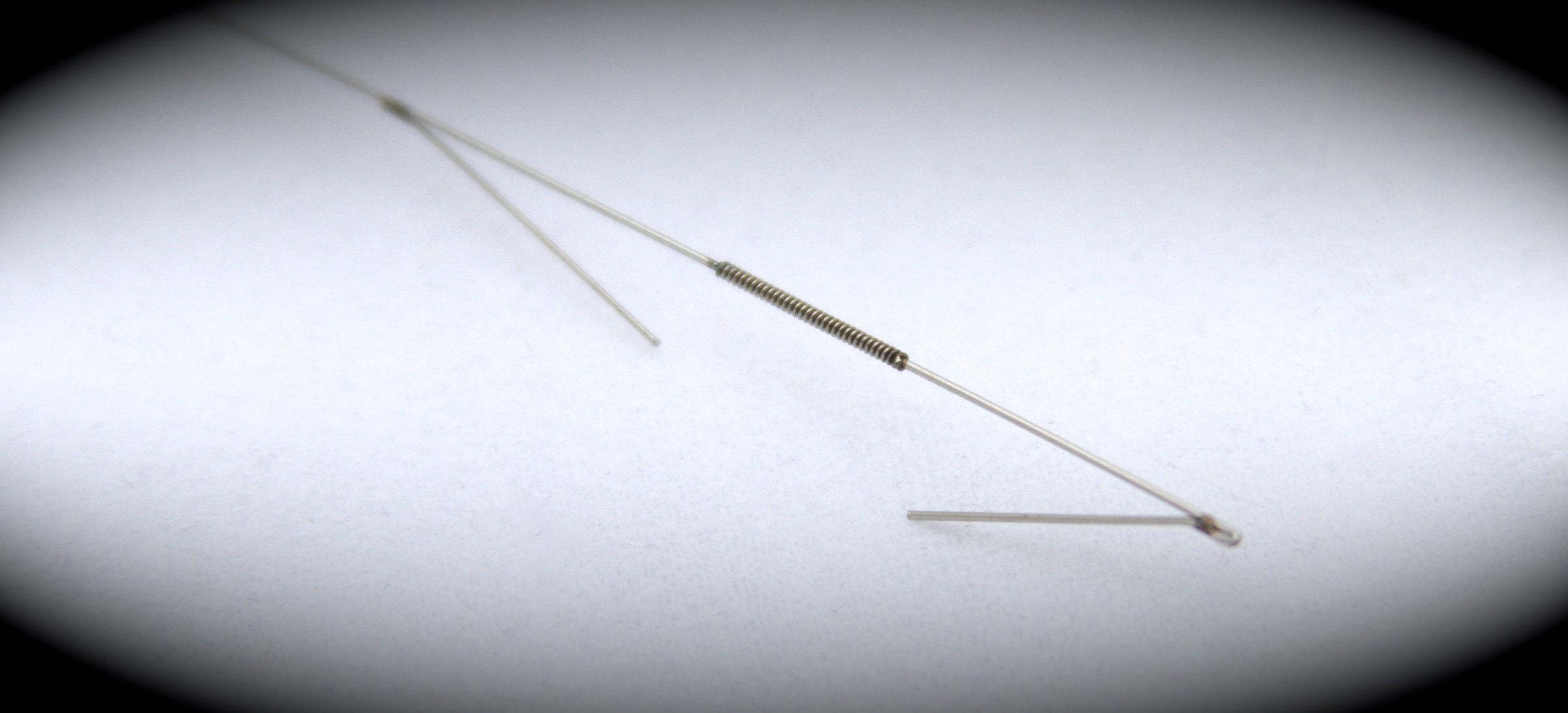

At Exacto Spring, we like to think of ourselves as custom precision spring experts. Clients from a wide variety of industries have relied on us for over five decades, and as we have mentioned before, we manufacture close to one BILLION springs and wire forms each year. With this in mind, we thought it would be a great idea to continue the discussion we started in our blog on Nitinol Wire and discuss some more of the raw materials used in our precision springs. We’ll begin with a very popular raw material—stainless steel.

Stainless Steel

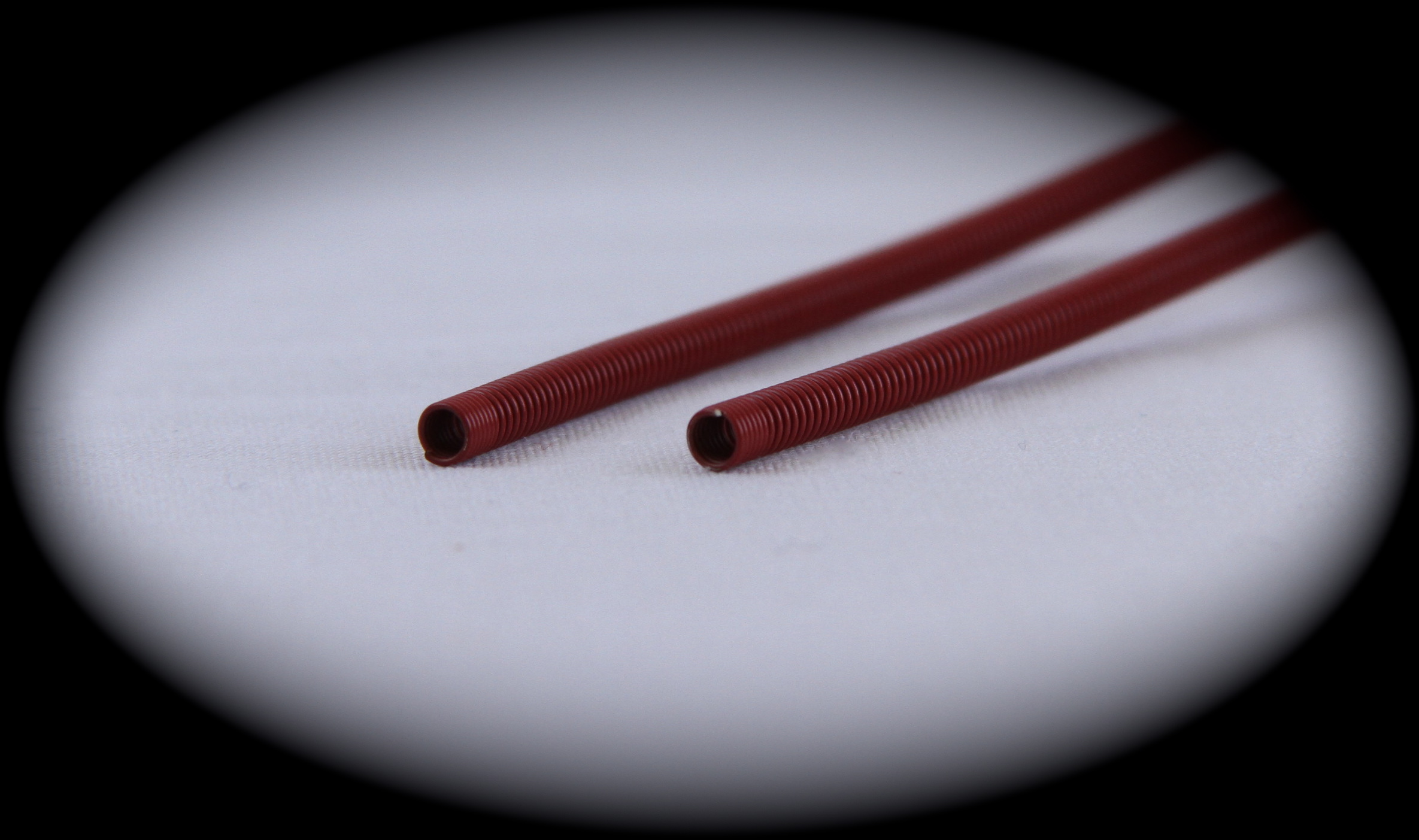

As you might expect, many springs need to be made of tough and resilient raw materials. Few things in the world embody toughness more than stainless steel. Often referred to as corrosion-resistant steel, it does not easily corrode, stain, or rust like regular steel. When it comes to manufacturing springs, there are a few types of stainless steel that we find ourselves using repeatedly.

304

This general purpose cold rolled steel is resistant to corrosion and heat, and is magnetic in spring temper.

302

302 has many of the same properties as 304, but it also has a higher carbon maximum.

316

This cold rolled steel is heat resistant, and boasts better corrosion resistance than 302. It is magnetic in spring temper.

17-7

This material is idea for high stress applications, as it’s harder in tensile strength than the other stainless options listed.

These are only a few of the many stainless steel wires that we utilize for our springs. For a full list or to pick the perfect one for your needs, contact one of the raw material experts at Exacto Spring today.