Blog

Chrysler Sets the Record Straight (and Ambitions High) for US Automakers

A few years ago, it was commonly accepted wisdom that the US auto industry would have to go the way of the dinosaur and steam locomotive. The argument essentially was that we as a nation couldn’t afford to bail out companies like Chrysler and GM with taxpayer dollars (all the while bailing out giant savings and investment banks). It seemed as though the late, great American automobile would go the way of the city of Detroit: into history and neglectful ruin.

That was a few, short years ago. But to (almost) everyone’s surprise and delight, the US auto industry hasn’t crumbled. GM has again reclaimed its place from Toyota as the world’s largest car manufacturer. Also, as of this month, Chrysler reported that it posted its first annual profit as a company since 2005, something to the tune of $183 in total revenue for 2011.

True, the Federal government still owns large swathes of some of these companies’ stocks; and the joke can still be heard making the rounds that “GM” stands for “Government Motors.” All the same, with the stock price of automakers’ on the rise again, the government may actually stand to gain a profit from selling off the remainder of its stock to private investors. And let’s not forget the 1.2 million American jobs that are dependent (at least in part) on the US auto industry for their business.

with quality compression springs, torsion springs, and extension springs. We make these springs from scratch at our 100,000 square foot manufacturing plant just 20 minutes’ drive north of Milwaukee, where we employ upwards of 150 people.n the US auto industry for their business.

Now that the Big Three are roaring ahead again (take a look, if you haven’t already, at this Chrysler commercial that played during the Superbowl this year), we can anticipate an uptick in our own sales. The profits of American vehicle manufacturers can already be seen trickling down to our own business. By the end of this year, Chrysler forecasts an annual profit of $1.5 billion, an amazing (almost ludicrous) prediction by anyone’s standards in 2009.

But that was then. Here’s to a great year of manufacturing, America

Announcing Our Sponsorship of Milwaukee’s Grand Slam Charity Jam!

What do Debbie Gibson, Trista and Ryan Sutter of Bachelorette fame, Naima Adedapo from American Idol, LeRoy Butler, Erica Hoyt, Grace Weber, former Miss America (and Broadway star) Kate Shindle, and live artist Shelby Keefe all have in common? The answer is fairly easy if you happen to hail from Greater Milwaukee.This March 10th, at the Potawatomi Casino in Milwaukee, these stars gave it their all in support of Hometown Heroes, a volunteer non-profit organization that serves the needs of “children, families, first responders, and veterans in need” by providing direct financial assistance, emergency aid, and partnerships with scores of important social service organizations. It’s a way of supporting the firemen who put out our fires, the downtrodden and dispossessed who want to give their children a meaningful future, and the soldiers and marines who have sacrificed so much for our country in foreign wars.

As a proud, long-standing member of the Greater Milwaukee community, we at Exacto Spring felt it only fit and proper to help sponsor this charity event. By donating to Hometown Heroes, we can only hope that our contribution furthers the ideals of what our city and community have, at their very best, always stood for. The Grand Slam Charity Jam brought out the best of the best in Milwaukee, and we at Exacto hope to continue in that spirit throughout the course of this year.

Spearheading Milwaukee’s Recovery from the Recession

A lot of people have heard the pundits and statistics claiming that the Great Recession is finally drawing to a close; that job creation and consumerism are on the verge of returning to their pre-2009 levels. Here in our own metro area, a certain level of optimism pervades. In one recent survey, 63% of Milwaukee businesses forecasted stronger sales for Q2, and just over 50% expect to be hiring more workers. There’s also talk these days on the national level about how manufacturing is spearheading the revival of the economy. Again, Milwaukee, with its long-standing portfolio of heavy industries, seems to be at the front and center of American manufacturing’s renaissance. In another recent survey, 82% of manufacturers predict significant sales growth for the 2nd quarter of 2012.

While it’s one thing to hear the good news from pundits and statistics, it’s another thing entirely to see the actual story unfold from the ground level – or in this case, from our own factory floor level. Here at Exacto Spring, we can attest to our own company’s strong growth not only by having the sales figures to prove it, but by the fact that we’ve recently 10% increase in the workforce to handle growth. New machine operators, onsite quality inspectors, and machine set-up personnel are all some of the new workers here. We’ve also made new machine purchases that will, we anticipate, increase our production output considerably.

In short, business is booming again here in Milwaukee. The time may soon come when the rest of the nation follows suit.

Good Manufacturers Make Good Neighbors: Helping Build Our Community for 30 Years

It’s probably clear that we at Exacto take a significant amount of time in helping to further our local community. For instance, our charity work has already been a consistent feature of this blog. But now we think it’s high time we talked about one of the longest-running community building initiatives we’ve undertaken: the Exacto Foundation of Grafton, WI, a privately registered company that works in close conjunction with Exacto Spring, serving the interests of our employees, neighborhood, and greater community in the same way that our company services the needs and interests of precision medical, aerospace, and automotive clients throughout North America.

Going on 30 years, the Exacto Foundation provides several vital and relevant services for the community in and around Grafton. One such instance is how the Foundation grants scholarships to students at local high-schools in Grafton, Cedarburg, and Port Washington. These scholarships allow students the necessary time and materials to enhance their education, and explore possible careers in manufacturing. In addition, we work with these same high schools to deliver manufacturing programs as part of their curriculum, giving students the chance to learn about machining both in and out of the classroom. Furthermore, we have a fund allotted for five college-bound kids every year that helps them pay their tuition. While we enjoy providing this service to the children of those who directly work for our company, we certainly are not averse to giving these prized scholarships to those whom we think best deserve them – whether they’re part of our Exacto family or not.

It’s always been our hope that these educational and economic development programs fill a vital niche for those who might otherwise be left behind in their pursuit of the American Dream. Being the long-standing precision manufacturers we are, we know full-well the time, labor, and investment required to turn something promising into something successful. In the end, it’s success that counts, and not potential. Our own hard work has paid off handsomely for ourselves, and by bestowing the fruits of our labor on others, we hope to inspire them to chart their own bold course in successful entrepreneurship and prosperity.

2013: The Year of the Car

Recently, Detroit’s Big Three unveiled their latest 2013 car, SUV, jeep, and pick-up truck models. While there are always the winners and losers in such a vast new array of vehicle platforms, the overall response is undeniably positive: a far-cry from just a few years ago, when pundits from America and from abroad were dismissing the American automotive industry as a has-been; a living fossil that was about to go the way of the ancient plants and dinosaurs that today comprise our fossil fuel.

But, as Mark Twain once quipped when confronted with his own obituary posted in The New York Journal, “The reports of my death are greatly exaggerated.” The same can now – several years later – be said safely of the American auto industry: not only has it recovered, but it’s posting record quarterly profits both in America and abroad (China recently surpassed North America for being GM’s largest market). With new eco-friendly engine technology that rivals anything the Japanese have built, as well as new customization offerings that enable drivers to – in essence – “personalize” their own car more than ever before in the history of automobiles, Motown’s Finest are not only running victory laps for this year, but they’re predicting continued job growth, profit generation, and facility expansion for at least the next two years, and more than likely well beyond.

This news can only be a good thing for the folks here at Exacto Spring, seeing as our springs are to be found somewhere in almost any domestic vehicle platform you might care to name. From stem to stern (and in-between), our springs enable cars and trucks to perform any number of critical functions. Thanks to our springs, gas tanks don’t ignite in the event of a head-on collision (and air-bags remain safely fused within their containers in the event there isn’t a collision). Fuel management, air conditioning, seat functioning, cruise control, and valves all likewise depend upon our technology to hold them together.

We’re glad to see the American auto industry holding its own in 2012. We’re proud that our springs have played an integral part in – quite literally – “holding American industry together.” In celebration of this new flourishing of America’s auto industry, we’re going to dub this coming year, 2013, “the year of the car.” Ladies and gentlemen, start your engines.

When You Need a Company That Speaks “Engineer-ese”

Almost any serious-minded manufacturer in America knows what they’re doing when it comes to machining and assembly of parts and components for the industries they work for. It is one of the things that have set our country apart from a lot of international competitors for so many years. While times have changed, and other countries in the world have caught up with a lot of America’s manufacturing proficiency (in some cases even surpassing it), there’s still a recognizable qualitative “voice” that bespeaks what American manufacturing is all about: innovative, fast-thinking, reliable, and serviceable. We don’t simply build other peoples’ ideas; we help them improve their own. That’s what we’d like to believe American manufacturing is all about, and that’s the spirit we try and embody here at Exacto Spring.

There’s a technical expertise at Exacto Spring that other companies simply don’t have. While many companies in America know how to comply with a client’s order down to the last detail (we can do that too), we at Exacto Spring can confer on the highest technical level with those who have initiated a particular project. With a staff of six in-house specialty engineers, our company knows how to speak the complex language of “Engineer-ese” like few others can. Our technicians aren’t glorified sales reps with a bachelor’s in Science; they are living, breathing experts in their respective fields. Any time you feel like reaching out to a company that knows how to speak “Engineer-ese”, know that Exacto Spring can do just that.

Exacto Makes Winter More Fun

Can you feel that bite in the air? After a long, hot summer, many parts of the country are only weeks away from real winter weather. A decent snowstorm already blanked parts of the northern Midwest in the first week of October, so we might be in for a long one. Trust us, being located just north of Milwaukee makes us experts when it comes to winter! It also turns out that many of our precision springs and wire forms find their way into some of the recreational equipment that make the cold, dark winter months just a little bit more enjoyable. It’s not a surprise considering that we have been the go-to supplier of compression, torsion, and extension springs for almost any industry you can think of for over 50 years.

Here are some just a few of cold weather activities that we help make better:

Skiing: Exacto supplies this multibillion-dollar industry with components for everything from equipment to resort supplies. Whether you are going downhill or cross-country, we just might have made your trip safer and more comfortable

Snowmobiles: Almost 50,000 snowmobiles were sold in the US in 2012. We might not have springs in every single one, but we do our part.

Ice fishing: This is one of Exacto’s sweet spots since we are very involved in the fishing industry. If you’ve never had a chance to ice fish, you really should give it a try. It is a unique experience and one that just wouldn’t be the same without the right equipment!

So, as you head out with the family to have a little fun this winter, we hope that one of our springs or wireforms will add to your enjoyment.

Exacto Spring: Bringing Quality Medical Solutions to MDM in the Twin Cities

The latest Medical Design and Manufacturing (referred to by anyone in the med-tech industry simply as MDM) expo will be held from October 30 – November 1 at the Twin Cities’ own Minneapolis Convention Center. Simply put, MDM is the most comprehensive and visionary overview of what lies in store for medical manufacturing in the coming months and years: the latest trends get covered, as so do the long-term paradigm shifts. Everything gets its time under the limelight, including the ways by which advanced cardiology and minimally invasive surgery are approached and practiced in North America and throughout the world as a whole.

The latest Medical Design and Manufacturing (referred to by anyone in the med-tech industry simply as MDM) expo will be held from October 30 – November 1 at the Twin Cities’ own Minneapolis Convention Center. Simply put, MDM is the most comprehensive and visionary overview of what lies in store for medical manufacturing in the coming months and years: the latest trends get covered, as so do the long-term paradigm shifts. Everything gets its time under the limelight, including the ways by which advanced cardiology and minimally invasive surgery are approached and practiced in North America and throughout the world as a whole.

With our extensive background in providing wire-form solutions for surgical processes including neurosurgery, cardiology, and minimally invasive surgery of all kinds, we at Exacto Spring are looking forward to meeting up with old friends and allies, as well as forging fresh business ties with a new generation of OEM medical manufacturers. Whether you’re a tier 1, 2, or 3 supplier, or whether you’re a Fortune 500 medical conglomerate, we’re looking forward to meeting you on the showroom floor. We’ll be exhibiting at Booth # 1141. See you there in the Twin Cities!

Exacto: Already Helping You Prepare for Next Year’s Black Friday

Nothing strikes fear in the hearts of retail workers like Black Friday. Historically it has been the major brick and mortar shopping day of the year. Millions of people line up and pour into America’s stores and malls to get their holiday shopping done, all at reduced prices. This year shoppers spent a mindboggling $11.2 billion at stores on Black Friday, which was actually 1.8% less than last year. The decline is misleading because what used to be one day of sales has now spread beyond the 24-hours that make up the Friday after Thanksgiving.

Interestingly enough, what is now an unofficial national holiday was once seen as a negative. Years ago, the term Black Friday first entered the lexicon as way of describing the “plague” that forced so many retail workers to call in sick the day after Thanksgiving. It then morphed into a description of the unpleasant and unwanted chaos that swarms of shoppers brought to shopping districts. Of course, once business saw the unbelievable money making potential of the day, they turned a negative into a positive and now they cheer on the barely contained chaos. It has gone from signifying a less deadly version of the Black Death to the day when stores start seeing black ink (or profits) on their ledgers.

At Exacto Spring, not only are we there on the shelves on that day – in TVs to washing machines and dishwashers, and even in furniture and toys – but it is also our year-long goal to keep manufactures and retailers of consumer products in the black always. We offer many different ways to keep our customers in the black including:

- Automation

- Special packaging and reliable delivery

- High quality parts that are easy to assemble and are defect-free

All of our 150 employees are dedicated to serving your precision spring needs so you’ll be prepared for next year’s Black Friday!

Over 50 Years of Quality American-made Products

As we begin 2013, we almost can’t believe that it’s been 53 years since we began manufacturing springs and wireforms in Rockford, Illinois. It was just 4 years later that we moved our operations here to Grafton, Wisconsin, and we’ve been producing our high quality, custom products here ever since. We are proud to say that, for each one of our products, we have and will continue to perform each and every step of the design and manufacturing process right here in the U.S.

This is a very exciting time for manufacturing in America. U.S. manufacturing ended the year on a positive note. American car companies, like Chrysler and Ford, are bouncing back from the recession, reaching record sales levels and promising to hire thousands of new American workers. Recent surveys indicate that a majority of American and (maybe surprisingly) Chinese consumers are willing to pay more for products with the “Made in USA” stamp. Meanwhile companies are undertaking massive “reshoring” initiatives and bringing jobs back to the US from overseas.

Here at Exacto, we like to think that we were ahead of the curve on that one. We’ve manufactured our quality products in the USA since 1960 and will continue to do so. Our custom springs and wireforms can be found across industries and applications, from automobiles to appliances. Exacto is everywhere you are; in 2000, we created the Exacto Medical division which continues to grow at an amazing rate in contributing to internal and external devices. Here’s to new applications, American manufacturing, and another 53 years!

Nitinol Wire for Medical Products

As many Exacto Spring customers might know, our spring and wireform products are used in so many industries and applications. From use in military parts to minimally-invasive surgeries, they’re pretty much everywhere. And, just as there are many varied uses for our products, there are many varied materials that can be used to make them. The material selected typically depends on the specific application—chances are, materials chosen for military parts will be different than those selected for minimally-invasive surgeries—but options abound.

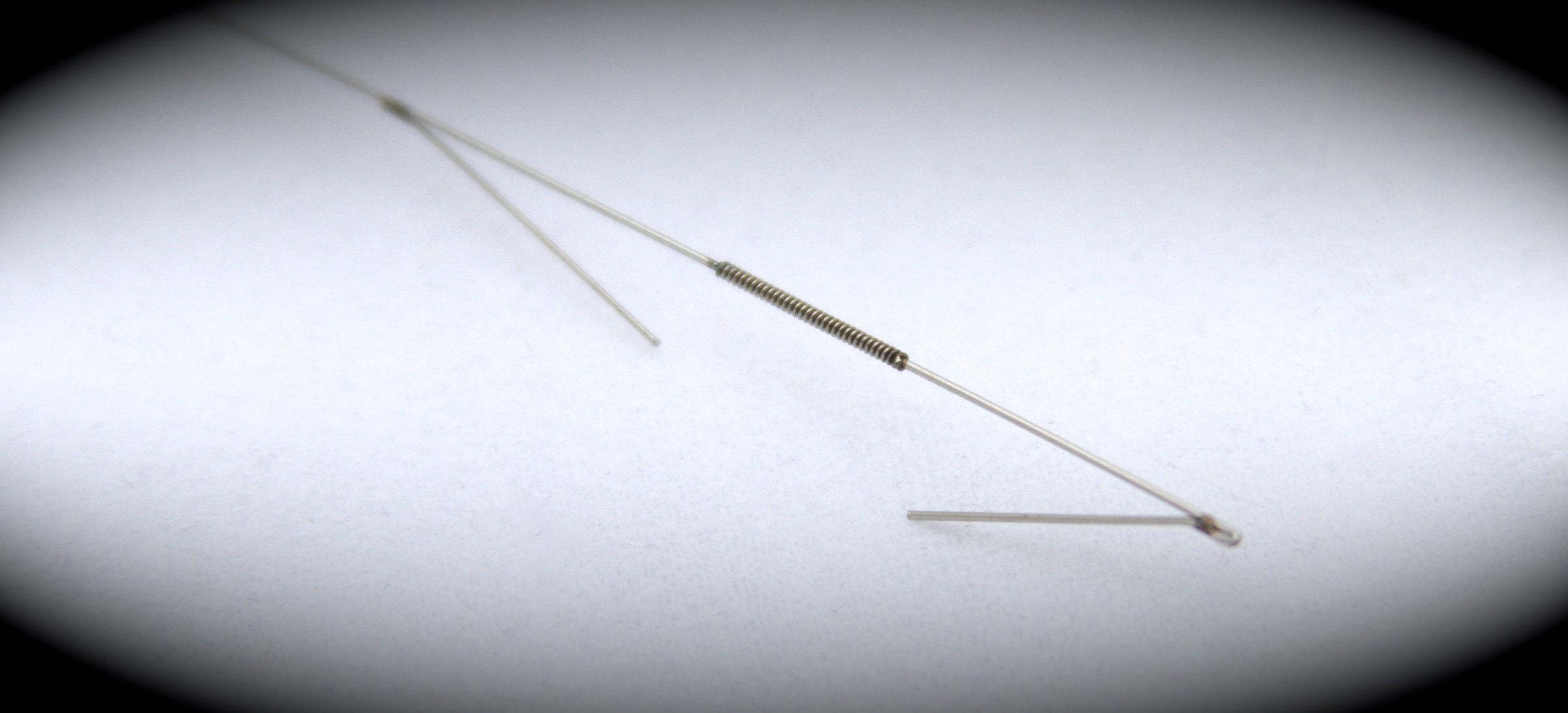

One material that is seeing ever growing popularity is Nitinol wire, which is most often used in medical applications. Nitinol is a material made of near equal atomic weight percentages of nickel and titanium, and comes in various grades; Nitinol #1, #2, #4, and #8 are used for medical applications, and Nitinol #5, #6, and #9 are used for other purposes. While it can be challenging to work with, Nitinol wire is a fascinating material that can be crumpled up and placed into areas of the body, and always returns to its shape (watch it in action here).

One of the premier manufacturers of Nitinol wire is Fort Wayne Metals, who supply about 90% of the medical wire used in the industry. Their Nitinol #1—the most common medical grade—exceeds ASTM F2063 standards for use in surgical implants, and is used in devices such as stents, stone retrieval baskets, stylets, and more.

Our experience and expertise, coupled with this material’s unique properties, create medical products that are second to none. Feel free to contact us with any questions.

The Importance of Tackling Custom Spring Development Early in Design

When designing for a new application, it’s imperative that one consider spring design from the beginning of the project. Thinking about the spring early on ensures that the spring is ideally suited for the application it will be used in. Saved for last, there are often problems with mating components, and stacked tolerances that override the spring. What’s more, when the spring is an afterthought, there’s often little to no consideration given to the environment. Will there be internal fluids that need to be protected against? How about external conditions such as humidity that need to be planned for?

Recently, we had a customer come to us with an emergency where they were going to market with their medical device, and bought an off-the-shelf hose clamp to hold a critical medical tube onto a customized fitting. It turns out that the off the shelf item was not anywhere near the proper design for their application and was causing failures days before they were going to market. The Exacto team instantly reviewed the design from their early stages and properly designed the clamp and solved their issue. In this specific case, we reduced the wire size to get the appropriate amount of movement and replaced the two sharp wires coming off either end of the original clamp with loops, a change that allowed the new clamp to be installed by a robot and eliminated the potential failures. In addition, we tweaked the overall shape so it would assemble with ease on their line.

Stock items are meant for a mass audience, but an individual application often calls for a custom solution and that is where Exacto will help. After we assist our customers, our next step is to manufacture samples, and provide the customer with a wide range of options. Typically, a customer doesn’t know exactly how strong their spring needs to be, and providing multiple options allows them to test each one and see what works best for their application, without a lot of time and cost.

You don’t get to call yourself “Exacto Spring” without being the experts on springs. We know what it takes to design a spring that will work, and that will enhance the overall quality of your part rather than detract from it. We get involved in many design processes and will do a complete feasibility study so that your spring meets the required amount of cycles in your application.

Investigating Raw Materials with Exacto Spring: Part 1 – Stainless Steel

At Exacto Spring, we like to think of ourselves as custom precision spring experts. Clients from a wide variety of industries have relied on us for over five decades, and as we have mentioned before, we manufacture close to one BILLION springs and wire forms each year. With this in mind, we thought it would be a great idea to continue the discussion we started in our blog on Nitinol Wire and discuss some more of the raw materials used in our precision springs. We’ll begin with a very popular raw material—stainless steel.

Stainless Steel

As you might expect, many springs need to be made of tough and resilient raw materials. Few things in the world embody toughness more than stainless steel. Often referred to as corrosion-resistant steel, it does not easily corrode, stain, or rust like regular steel. When it comes to manufacturing springs, there are a few types of stainless steel that we find ourselves using repeatedly.

304

This general purpose cold rolled steel is resistant to corrosion and heat, and is magnetic in spring temper.

302

302 has many of the same properties as 304, but it also has a higher carbon maximum.

316

This cold rolled steel is heat resistant, and boasts better corrosion resistance than 302. It is magnetic in spring temper.

17-7

This material is idea for high stress applications, as it’s harder in tensile strength than the other stainless options listed.

These are only a few of the many stainless steel wires that we utilize for our springs. For a full list or to pick the perfect one for your needs, contact one of the raw material experts at Exacto Spring today.

Investigating Raw Materials with Exacto Spring: Part 2 – All the Rest

For Part 2 of our raw materials series, we’re taking a look at some of the other materials we make use of here at Exacto Spring.

Music Wire

Music wire is cold drawn high, with uniform tensile strength. It is the most common material in our industry. In addition to being used to manufacture high quality springs and wire forms, it is also suitable for high stress applications. It is available in plain or coated varieties, depending on application.

Chrome-Silicon

This is the material to use when you need your spring wire to survive and thrive under high stress situations. It’s an alloy steel that’s cold drawn and heat treated before fabrication, enabling it to withstand stress, shock, impact loading, and extreme temperatures.

Phosphor Bronze

Cold drawn phosphor bronze is one of the most popular copper-based alloys in the spring making world. It exhibits good electrical conductivity and corrosion resistance. An interesting side note: it is used in some modern keyboard instruments, as well as other musical instruments.

Oil Tempered

Also known as ASTM A229, this general purpose high-carbon steel wire is cold drawn and heat treated before fabrication. It’s a popular choice due to its low cost when compared with other materials.

Inconel

Our final material is a member of the superalloy family. As that designation suggests, this nickel-chromium based wire—available as Inconel 600, Inconel 718 and Inconel X-750—is perfect for high temperature applications. Cold drawn—and in the case of 718 and X-750 precipitation hardened after fabrication—Inconel also provides good corrosion resistance at high temperatures. It is important to point out that Inconel is a trademark of the U.S. based company, Special Metals Corporation. They are also the makers of Incoloy, Nimonic, and Udimet.

So there you have it, a quick look at some of the more common wires in the industry. Here at Exacto Spring we make use of these materials every day to create our industry leading springs and medical products. If there’s a material we didn’t list that you’re interested in using, don’t worry—odds are we have it or can get it quickly.

American Manufacturing: Where Are We Today?

As American manufacturing is seeing a welcomed comeback, and national MFG Day is right around the corner (October 4, 2013), it’s as important as ever to celebrate this day of industry recognition and help keep the momentum going. According to the sponsors of the event, this day “provides manufacturers with an opportunity to tell their company’s story, dispel outdated myths about manufacturing, inspire a new generation of manufacturers, and connect with their communities.”

Today’s state of American manufacturing is luckily a different story than it was in recent times. In fact, August’s factory production rates were at their highest in over two years. According to this article, major companies throughout the country are “re-shoring and American entrepreneurship is growing in leaps and bounds thanks to more affordable tools, like laser cutting, 3-D printing and even robotics. It’s a great time to be a maker or entrepreneur.”

Thanks to a general mindset of bringing manufacturing back, coupled with the overall attractiveness of manufacturing in the U.S., reshoring is bringing business back home, and the pace seems to be steady. Many don’t want to go overseas to do business anymore, and the hope is that as this trend continues, the pace will go from steady to heavy.

Accordingly, many American companies are getting involved in their communities and local schools and universities, providing information about the value of careers in manufacturing. As there is a worry over the current skilled labor shortage, companies—and events such as MFG Day—are working to combat the problem by attracting younger generations and getting them excited about the industry.

At Exacto Spring, not only are we proud to be an American manufacturer, but we’re actively involved in the focus on manufacturing’s return. Specifically, we are involved in many local programs, such as our partnership with GPS Education Partners, that work with students. The goal is to get students involved and interested in manufacturing at a young age in the hope they will consider future careers and opportunities in the industry. As American manufacturers, we understand the importance of manufacturing in our economy, as well as bridging the skills gap. Additionally, we offer two-year apprenticeships that provide students with an overview of manufacturing skills, though specifically in spring making techniques. We are proud to be American manufacturers and we certainly hope to continue the trend for future generations.

Manufacturing might not be exactly what it used to be, but with ingenuity, innovation, and education, we can all help make it better than ever.

The Disclosure of Conflict Minerals Use in Automotive Supply Chains

As manufacturing continues to experience growth, so has the automotive industry. In recent months, the auto industry has seen stronger sales and more sustained recovery, according to this article by theDetroit Free Press. With increased sales comes an increased demand for conflict minerals disclosure.

The use of “conflict minerals” has affected all manufacturing industries, and will be in full effect by the end of 2013. Specifically, the conflict minerals’ requirements are outlined in the Dodd-Frank Wall Street Reform, created by the U.S. SEC. They refer to the prohibition of use of minerals and materials from “conflict” areas, more precisely the Democratic Republic of Congo. The minerals in question—tin, tungsten, tantalum, and gold—are restricted from use in American supply chains. According to this article, manufacturers in areas such as the electronics or automotive fields will need to accurately report whether or not these conflict minerals appear in their supply chain.

When it comes to the auto industry, auto manufacturers and other manufacturers in the automotive supply chain, such as us here at Exacto Spring, now need to confirm where the materials are being sourced from. Since auto sales have increased, there has been more of a demand of these reports. According to this article from Automotive News, the conflict minerals’ ruling has forced those in the auto industry to review their supply chain in a whole new view. Why? As stated in that article, those materials are used in a variety of automotive products, “causing a need for the supply chain to get into the data and reach out to suppliers.”

Here at Exacto Spring, we have been busy providing customers letters stating where we have received our materials. This is something that is happening up and down the supply chain, and with a higher production of cars, is something affecting all those in the auto industry. Whether or not you’re involved in the auto industry, it’s still pertinent in today’s manufacturing world to ensure your materials are conflict-free.

2013: A Year of Expansion for Exacto Spring

2013 has been an exciting year for the entire Exacto Spring family! As the nation’s economy has rebounded from a few tough years, Exacto Spring has flourished. Positive movement in the medical, auto, and aerospace industries brought a wave of new business and customers to Exacto Spring in 2013.Thanks to a spike in orders, we were able to make some big changes in 2013. Here are some of the highlights:

Expansion

We purchased another building for use as a storage and receiving center. This new 25,000 sq. ft. facility, which we are calling Exacto West, allows us to house all of our raw materials, which increases our manufacturing space at our main facility for future growth. The new building brings our total square footage to 150,000. Additionally, we have been hiring in all areas of our company this year due to our company’s growth.

New Equipment and Capabilities

By adding new coiling equipment, we are reaching new markets for the spring side of our business. The new fleet of machinery also expands our capabilities, including the addition of small run productions up to .250 wire diameter and our niche of .156 and below. We have now over 150 pieces of production equipment. We have also increased automation and we’re constantly innovating new products in order to reduce costs, exacto-ize our equipment, and better serve our customers.

So what does 2014 hold for Exacto Spring? We firmly believe that the global economy has turned a corner, and that 2014 will be just as strong as 2013.The best part is that thanks to our expansion this year, we are prepared for whatever 2014 has in store.

Our Niche in the Spring Market

Every company and every business has its own niche—their capabilities or services that comprise their business and make them known in the industry. For us here at Exacto Spring, we have created a niche with our springs and wire forms for the past fifty-four years.

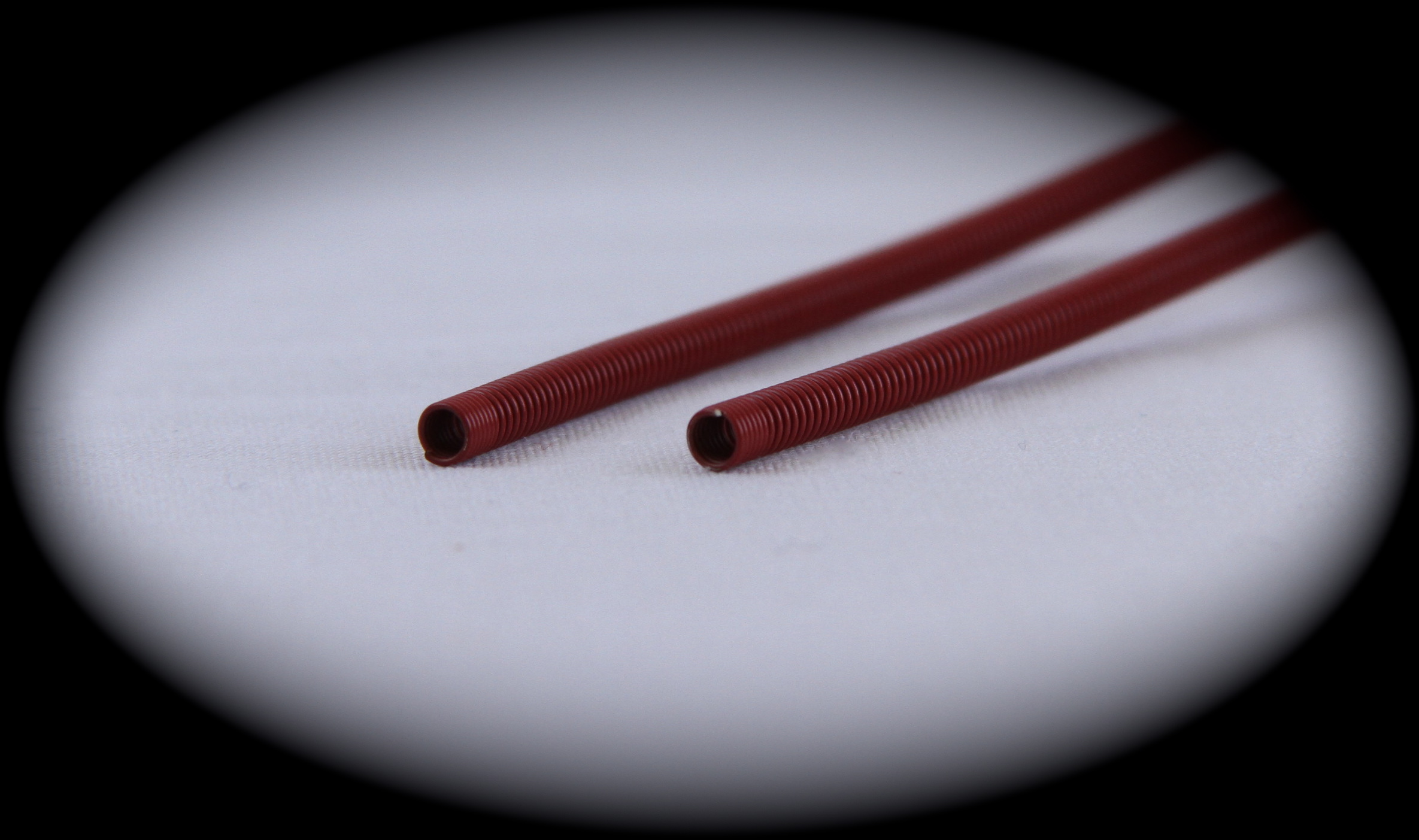

Specifically, we are skilled in producing compression springs (push to get force), torsion springs (twist to get force), and extension springs (extend to get force). Wire diameters of these custom springs for our customers range from 0.002” to 0.006”. We are proficient in tight tolerances and springs of all sizes—we have manufactured them in sizes ranging from 0.005” long to 1,000’ long. Over the years, we have perfected our springs to be applicable for all industries, and we can supply them in all volumes. Our customers are located in 22 countries, and we make thousands of part numbers each year.

Here at Exacto, we are proud of our high quality, engineering design and assistance, and our services that go the extra step—including working on parts that need extra attention, packaging, and automation. We are consistently examining ways to make our products more innovative and our processes to better meet our customers’ needs. We will continue to strive to become better in our niche—and we hope to become your niche supplier!

Our Trip to the MDMW Show!

It is that time of year again—the time for the MDM (Medical Device Manufacturer) West trade show! As we have been doing for years, we attended and exhibited at the show, which took place February 11-13th.

The trade show, which is the nation’s largest medical device conference that brings together suppliers and customers and offers in-person events and educational events, is an opportunity for us to showcase Exacto Medical. Exacto Medical is the piece of our company that markets the medical industry, as wire forming is more commonly used for medical applications. We have found that people sometimes may think springs aren’t applicable for the medical industry, so they don’t first think of us when searching for a supplier. Due to this, we have learned to market this part of our company differently, so that we can reach the right people in the medical industry and show what we have to offer.

This is why attending the MDM West show every year is an important part of our business. Here, we can meet with other professionals in the medical industry and showcase how our capabilities can fit their needs. We brought samples with us to show off, so that we can highlight some products we are able to manufacture. Since we are a custom shop, the show also gives us the ability to brainstorm with potential clients—typically engineers and buyers from medical companies—about how we can best meet their needs.

This year was no different; we were excited to showcase Exacto Medical and meet new people in the industry. We can’t wait until next year!

Auto Industry Lightweighting: The Next Big Thing

It’s auto show season around the country and the world, and that means a lot of excitement for industry professionals and car enthusiasts alike. This is where auto makers reveal their latest models, and also where trends in the industry are seen and examined.

Of all of the top trends, one of the biggest seems to be lightweighting—everyone is talking about it. At theDetroit Auto Show, Ford unveiled their 2015 F-150 pickup, which weighs about 700 pounds less than the previous model. The reduction is thanks to a high-strength aluminum alloy that is also said to help prevent dents and dings.

At last month’s Geneva Motor Show, attendees got a look at the 2015 Mercedes Benz S63 AMG 4Matic Coup, boasting a lightweight body and lightweight alloy wheels. The car made its U.S. debut at the New York International Auto Show, April 18-27. Also unveiled there is the Alfa Romeo 4C coupe, featuring a lightweight carbon fiber and aluminum body.

Whatever the material—aluminum, magnesium, steel—there’s no denying that auto makers and suppliers are looking to lighten the load. Benefits include greater efficiency and better handling, and according to makers of lightweight automotive steel, safety is uncompromised. While manufacturers are still working out ways to integrate lightweight materials while keeping it cost-effective, it’s clear that they are all eager to introduce these materials and vehicles to the market.

This month will even see the Global Automotive Lightweight Materials conference in London, a supply and manufacturing summit that proves the interest in and focus on the subject is significant.

As most of us know by now, the auto industry has made a major comeback, and the innovation, technology, and quality is unprecedented. This is and will continue to be true for vehicle lightweighting, and it will be interesting to see what the future holds. Here at Exacto Spring, we serve all automotive tier levels with our precision springs and wire forms. The automotive industry wants the best and with us, they will get the best. We are excited to partner with the auto industry and we’ll certainly be there to provide the highest quality products.

The Importance of Being a High-Quality Supplier

It’s no surprise that recalls, especially large-scale ones, can be quite costly for big auto manufacturers. The recent string of GM recalls really hammers that point home. Recalls can also show us the dire importance of each component, big and small, in a machine with so many moving parts. It stresses to manufacturers the importance of working with high-quality suppliers who can minimize the risk by delivering well-made parts that are far less likely to cause these kinds of problems.

As many of us know by now, the massive General Motors recall was triggered by faulty ignition switches in millions of vehicles. GM changed the design as a part of cost-saving meaures, and it ended up costing the automaker millions of dollars when its vehicles didn’t work as intended. If it wasn’t for the ignition switch problems, GM could have seen profits comparable to the ones it pulled in the first quarter of last year, around $865 million. Instead GM saw its first quarter profits decline by 86% this year, according to this report. While weakness in some overseas markets played a part in this huge decline, most of that loss can be attributed to the costs associated with this, and more recent, recalls.

One of the components that was in the switch was a spring. This is why, no matter what component they are producing, a manufacturer needs to set its sights on being a high-quality supplier. Here at Exacto Spring, we may manufacture precision springs and wireforms. Our products are found in anything from cars to appliances, and we take great care to ensure that they’ll keep these complicated devices running smoothly and follow everything that is stated on the control plan, PPAP, prints, etc., No exceptions! Everything we do on the floor has been approved by the customer, and we never stop trying to create better components. Our mission is to be a high-quality supplier because we know how integral each component is to the finished product

Our Unique Customization Process for Springs and Wire Forms

At Exacto Spring, we are well-known for the springs and wire forms we manufacture every year. We are so different from our competitors because we work closely with each individual customer to create custom springs and wire forms for their unique needs.

Each and every time we manufacture products, we focus heavily on the customer’s specifications and needs. Typically, we work with engineers, program managers, buyers, R&D people, and anyone that is working on the actual product in order to custom make the exact spring or wire form needed.

When a product is being made, each component must be made properly and with high quality materials. One of the needed components may be a spring or wireform. A client comes to us to find out how to design and produce springs and wire forms for their unique product.

The customization process varies for each customer. Usually, the customer will come to us with a design and other parameters that we can work with. Our team then works with the customer supplied specifications and assists in the final design. Approximately 80 percent of the time, prints need to be adjusted once we see them, so it is important that our engineers work with our customers in order to finalize the design.

One of the more consistent specifications is ensuring the spring is safely stressed. Therefore, it is essential that the design of the component is accurate and that the part will actually work in the conditions of the end product. It is our job to make sure the parts meet the necessary amount of work cycles.

How do we go about this? It is necessary for us to take a good look at the final application and review the conditions and environment in which the spring will be placed. Proper heating of the part is important for maintaining its memory and ensuring it can withstand and exceed certain conditions. This allows our customers to be confident the parts will succeed in their function.

Our customers consistently call and rely on us to provide them with materials necessary to complete their products and to guide them along the way. We have built trust with our customer base and continue to be their go-to spring and wire form manufacturer.

National Manufacturing Day and the Importance of American Manufacturing

The American manufacturing sector continues to grow, but many people have no idea just how important manufacturing is to our economy. Every year National Manufacturing Day tries to change that. On October 3rd manufacturers all over the country will open their doors to the public to show them just how integral their businesses are to our lives.

Our manufacturing sector has seen some good news in recent months. In August, manufacturing expanded in its fastest rate in over three years. The Institute for Supply Management’s gauge of production hit a four-year high. The measure of new orders climbed to its highest level in a decade.[1] But this recent growth means nothing if manufacturers can’t continue the momentum in the coming decades.

That is why National Manufacturing Day exists. When manufacturers invite students, parents, public officials, educators, and the media to their facilities for tours and events, they can show them why they are needed. They can rattle off statistics like how many American jobs the sector supports (over 17 million) or how manufacturing makes up 12.5% of our GDP.[2] They can give people an insight into how the products and components they rely on every day are produced. They can show people the vast array of job opportunities the sector offers for skilled, educated workers.

This is perhaps the most important part of National Manufacturing Day. If people like educators and students realize that the importance of the manufacturing sector and see the well-paying jobs it offers, more people may be encouraged to seek out the skills needed to perform these jobs. A “skills gap,” a difference between what skills employers need and what skills the labor pool has, would be crippling for manufacturers. Events that shed light on the significance of manufacturing and the need for skilled workers can help us make sure that these companies can continue expanding.

So remember to check out National Manufacturing Day’s website and try to find an event near you!

[1]http://abcnews.go.com/US/wireStory/us-manufacturing-grows-fastest-pace-years-25217351

[2]http://www.mfgday.com/resources/manufacturing-day-infographic

We Have Won “Supplier of the Year” Award

Here at Exacto Spring, we pride ourselves on being a top-tier supplier, and it’s always a great honor to be recognized for our top-quality work. On September 24th, American automaker General Motors gave us a Supplier of the Year award. This award is given to a small number of suppliers that have exceeded all expectations and delivered high performance this year.

General Motors has over 18,000 suppliers in locations all over the world, but only 83 were given the Supplier of the Year award last year.[1] This means that less than one percent of their suppliers are recognized with this award each year. What GM looks for is great cost solutions, solid crisis management skills, and the ability to develop innovative technology. These suppliers need to provide great support to the entire GM organization and exceed the automaker’s strict quality performance criteria.

General Motors has a wide selection of vehicle brands, so these top-tier suppliers need to be able to manufacture parts for vehicles as varied as the GMC Sierra pickup truck, the Cadillac CTS luxury sedan, the powerful Chevy Camaro, and everything in-between. We have been a supplier for GM for decades, so we know all about their high quality regulations for suppliers. We’re excited to be recognized for our work, and we look forward to providing General Motors and other automakers with top-notch work for years to come.

[1]]http://www.mlive.com/auto/index.ssf/2013/03/gm_announces_new_top_award_sup.html

The Automotive Industry and the Push for Better Fuel Economy

It’s no secret that the automotive industry has made a spectacular recovery in recent years. In September many automakers saw sales of new vehicles, especially compact cars and pickup trucks, increase yet again thanks to an improving economy and rising consumer confidence. The average price of vehicles is also on the rise, climbing to $32,500. This is great news for automakers (and component manufacturers), but we’ve approached a very important time of year for the automotive industry. Automakers have begun building their new models for 2015.

Whether it’s a radically changed and redesigned model, like the new Ford F-150, or a vehicle that merely adds some more power or features to last year’s model, automakers need to keep track of important trends.

Currently, one of the biggest focuses for the industry is fuel economy. The US and some other countries have set new fuel economy standards that automakers will have to abide by. Whether through lightweight techniques (like the use of more aluminum in vehicles like the F-150) or the development of more efficient engines and hybrid cars, the US expects automakers’ vehicle lineups to have an average fuel economy of 36.6 miles per gallon by 2017. By 2025, that increases to 54.5.

At Exacto Spring, we’re currently working on a number of projects that concern fuel management systems, and we’re even involved in the design and testing phases of projects that may not see the light of day until the end of the decade. And we know that, regardless of current trends and the relentless forward march of technological advancement, high-quality components will be needed in the vehicles of 2015 and beyond. Some may not realize just how important springs and wireform products can be, but as we’ve seen with recent recalls even a small component can cause a huge problem if they’re not properly manufactured or compatible with a redesigned vehicle. We’ll continue to offer automakers the best springs we can manufacture, and we can’t wait to see where the industry goes from here.

The Medical Device Industry

In 2014, Exacto has hired dozens of production personnel to keep up with our growing programs in the medical side of our business. In addition, our custom built equipment for these special programs is mostly made in-house to meet our stringent customer requirements. The machines we use need to be custom built as no job is the same and this type of equipment is not available to purchase. Bending wire to a certain shape does not come easy in medical, especially when you’re adding components to the product and holding the toughest requirements that the Food and Drug Administration (FDA) requires.

The FDA is revising the current good manufacturing practice (CGMP) requirements for medical devices and incorporating them into a quality system regulation. The quality system regulation includes requirements related to the methods used in, and the facilities and controls used for, designing, manufacturing, packaging, labeling, storing, installing, and servicing of medical devices intended for human use. This action is necessary to add preproduction design controls and to achieve consistency with quality system requirements worldwide. This regulation sets forth a framework for device manufacturers to follow and gives them greater flexibility in achieving quality requirements.

The FDA requires detailed studies, protocols, and documentation. Customers also require performance qualifications and operational qualifications for projects, requires a lot of studies, protocols, and documentation of processes, all of which is done by Exacto. Checking dimensions of the devices, checking the worst case scenarios and stacked tolerances require a lot more work, written and documented procedures on equipment. These required documents and studies are produced to the FDA along with the projects. Exacto has all the measuring equipment, using which precise measurements can be taken (can be measured to the microns). All these help Exacto to meet and exceed the requirements set by the FDA. We are also investing in new quality and associated equipment to check the products so that they meet the new and changing required specifications.

Whenever a sponsor intends to conduct a study that is not covered by a protocol already contained in the IND, the sponsor can submit to the FDA a protocol amendment containing the protocol for the study. Such study begins if the following conditions are met:

- The sponsor has submitted the protocol to FDA for review

- The protocol has been approved by the Institutional Review Board (IRB) with responsibility for review and approval of the study in accordance with the requirements of part 56. The sponsor may comply with these two conditions in either order.

Learn more about our capabilities on our website.

Looking Back at 2014 and a Look Ahead to our 55th Year

With our company heading into our 55th year of operation, we like to think that we’re not showing our age one bit. Nothing shows this better than our evolution in 2014. As a company, we grew greatly in skill and capacity, growth spurred on by our customers’ continued business and trust in us.

Increased Manufacturing Capabilities

Within the last year, we increased our workforce by 10%, bringing in more talent and capability. We updated our infrastructure, including major investments in new equipment – in fact; it was our biggest years ever for new equipment procurement, bringing in the latest spring-making machinery.

Using Technology to Succeed

Through the investment of capital in a new computer system, we have updated how we manage information and distribute it to customers. This provides for better record keeping and better customer service, as well as increased awareness of the big picture on our side.

Organic Growth

Through customer involvement and increasing our capabilities, we continue to grow. We have roughly 5,000 active part numbers, signifying competency in a variety of industries and applications. We have nearly 1,000 customers located in 20 countries, and we value each of them equally. We continue to see organic growth that we feel reflects our ability to produce quality springs for a variety of applications.

With our anniversary coming up in 2015, we plan on continued growth, and for another 55 years after that. We will continue to seek out new opportunities, in new industries, and prepare for the future. At Exacto Spring, we will always have improvement and innovation on our minds, and we look forward to working with you now and in the future.

Exacto Spring Gives Back to its Community by Supporting Hometown Heroes

International turmoil and vendetta tend to have far reaching consequences resonating out through the years to follow, affecting hundreds of thousands of lives. The black day September 11th, 2001 was such an event of conspiracy and violence that triggered life altering changes all over the United States.

The families of the dedicated men and women of the US Military have perhaps paid the highest price. Estimates show that since 9/11, more than 5,000 children have lost a parent to the ongoing war against terrorism. These young ones grow up without the aegis of a beloved father or a loving mother, and they require a lot of grief counselling to move on with their lives. They need to connect emotionally with other individuals who can understand their pain and insecurities. Furthermore, the recent movie “American Sniper” has taken the country by storm and has given Americans an inside look in war.

This is where the revolutionary Camp Hometown Heroes in Wisconsin steps in. It is a week long summer camp for young individuals, between ages seven and seventeen, who have lost someone of significance serving in the US military. It is a profoundly national cause espoused by faces of renown like superstar athlete Aaron Rodgers from the Green Bay Packers. The volunteers of Camp Hometown Heroes include considerate and responsible citizens from all over the nation who invest time and money to ensure that the bereaved young ones can cope with their loss, understand the significance of the sacrifice made by their parents and realize the fact that they can go on to have rewarding lives and careers.

It is a saga of positivity and catharsis that is shouldered by the paediatric counsellors from Kyle’s Korner and willing corporations eager to fulfil their social responsibility and be associated with an extremely patriotic charitable cause.

The Grand Slam Charity Jam is an event that raises funds for Camp Hometown Heroes and other charities of consequence. It is held annually and marks the culmination of the noble intentions of a clutch of companies sponsoring the Wisconsin visit for children from 22 states.

Exacto Spring Corporation such a name. One of the leading suppliers of high quality, durable springs to the US army, it has pledged to support 125 kids so that they can join Camp Hometown Heroes and become part of a community which understands them.

Given the place of honour as a Gold Sponsor at the Grand Slam Charity Jam event, Exacto prides itself on being a true supporter of the valiant of the country who regularly lay down their lives to protect the democracy and sovereignty of not only the nation, but the whole world!

To know more about Exacto Springs Corporation, please call 262.377.3970. To sponsor a camper, visit http://www.hometownheroes.org/donate/.