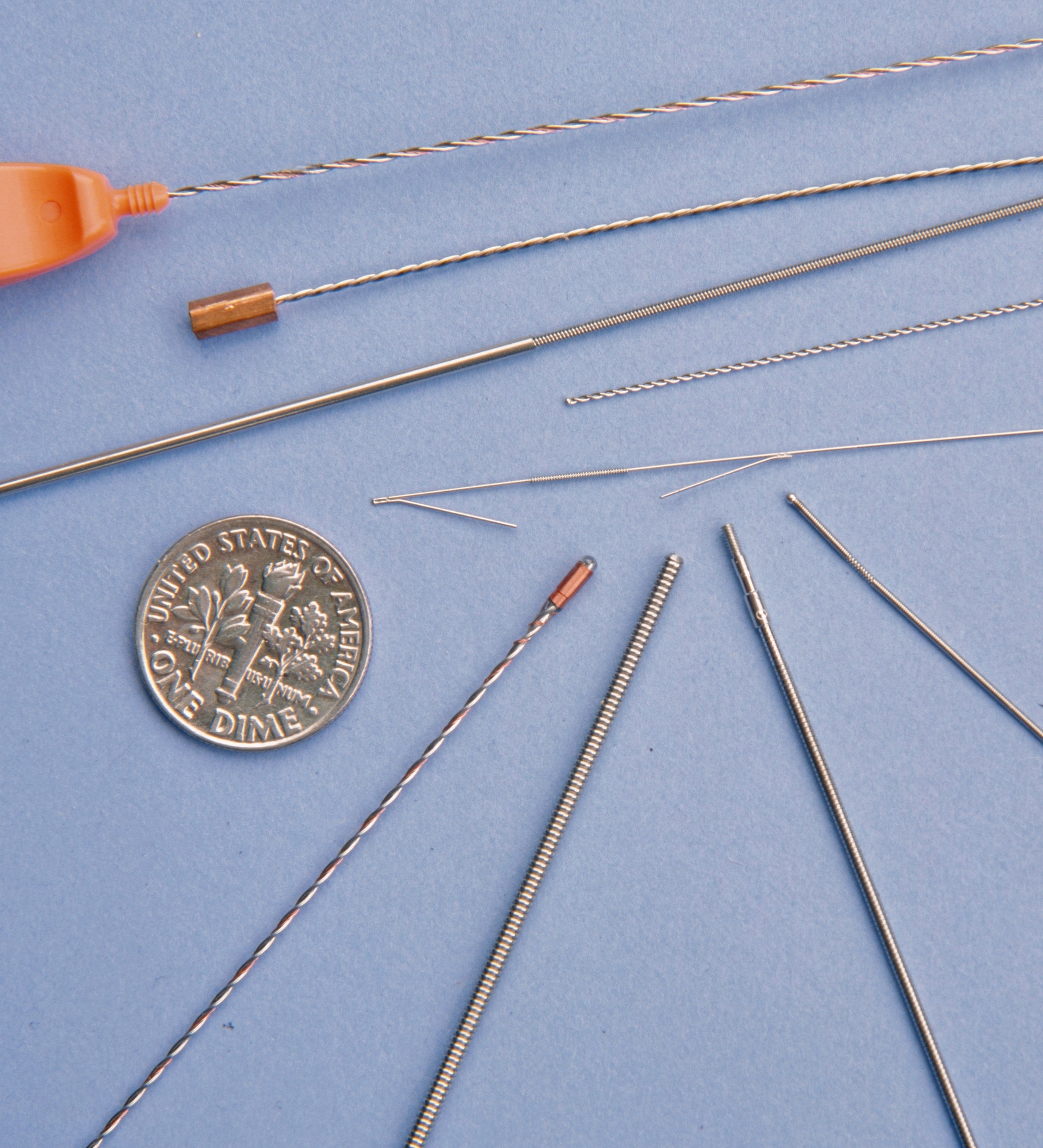

Components for Medical Device Industry

Exacto’s custom, precision medical products are manufactured to meet your most stringent precision medical product performance requirements – and those of your end users. Our process starts with complete custom medical product engineering services, delivered by a staff of application engineers with a wealth of experience in meeting the unique challenges of medical wireforming applications. It continues with the most advanced wire manufacturing processes you’re likely to encounter anywhere – including your own facilities. Processes are governed by sophisticated Statistical Process Control wireforming techniques, to ensure you of consistently high quality precision medical wireforming in our ISO Certified Class 7 clean room.

We provide a state of the art multi-sonic washing system, to include citric passivation, three rinse stations, and two in-line drying stations ensuring you the proper cleanliness of your precision wires. Exacto Spring provides the highest quality each and every time; from the fully automated Clean Room process to the monitoring of the water used to feed the system, giving you peace of mind. We close the loop with truly outstanding customer service and a proven track record for delivering your medical products on time and within budget.

Exacto’s Primary capabilities for the Medical Device Industry include but are not limited to:

- Multi-Filers

- Straightening

- Sheaths

- Reinforcement Coils

- Steerable wire products

- Stylets/core wires

- Wire Forming

- Coils

- Snares

- Robotic Laser Welding

- Thermo-Soldering

- Thermo-Coupe Welding

- Class 7 Cleanroom

- Precious Metals

- Assemblies

- Introducers

- Twist Wires

- Multi-Component Assemblies

- Citric Passivation

- Multi-Sonic Washing

- Tig Welding