At Exacto Spring, we are well-known for the springs and wire forms we manufacture every year. We are so different from our competitors because we work closely with each individual customer to create custom springs and wire forms for their unique needs.

Each and every time we manufacture products, we focus heavily on the customer’s specifications and needs. Typically, we work with engineers, program managers, buyers, R&D people, and anyone that is working on the actual product in order to custom make the exact spring or wire form needed.

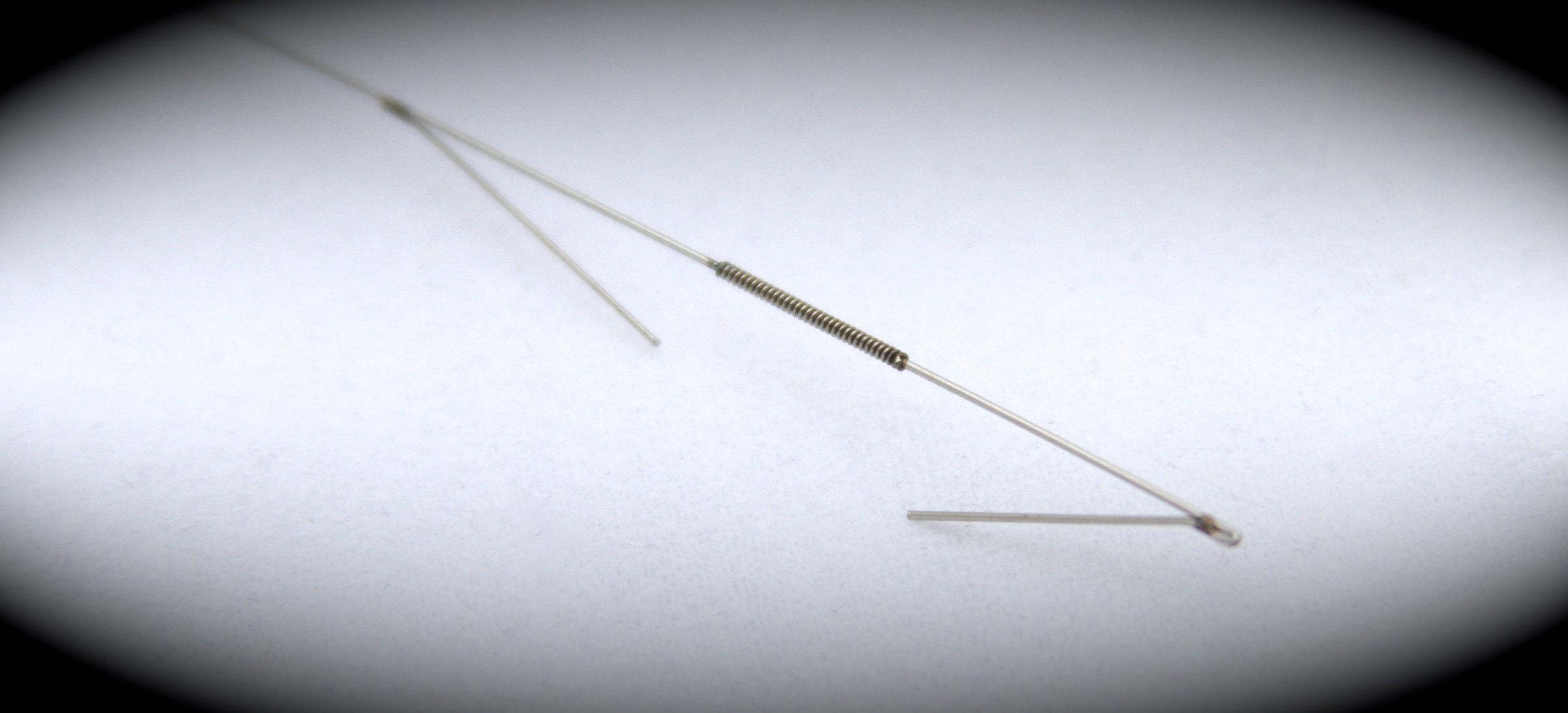

When a product is being made, each component must be made properly and with high quality materials. One of the needed components may be a spring or wireform. A client comes to us to find out how to design and produce springs and wire forms for their unique product.

The customization process varies for each customer. Usually, the customer will come to us with a design and other parameters that we can work with. Our team then works with the customer supplied specifications and assists in the final design. Approximately 80 percent of the time, prints need to be adjusted once we see them, so it is important that our engineers work with our customers in order to finalize the design.

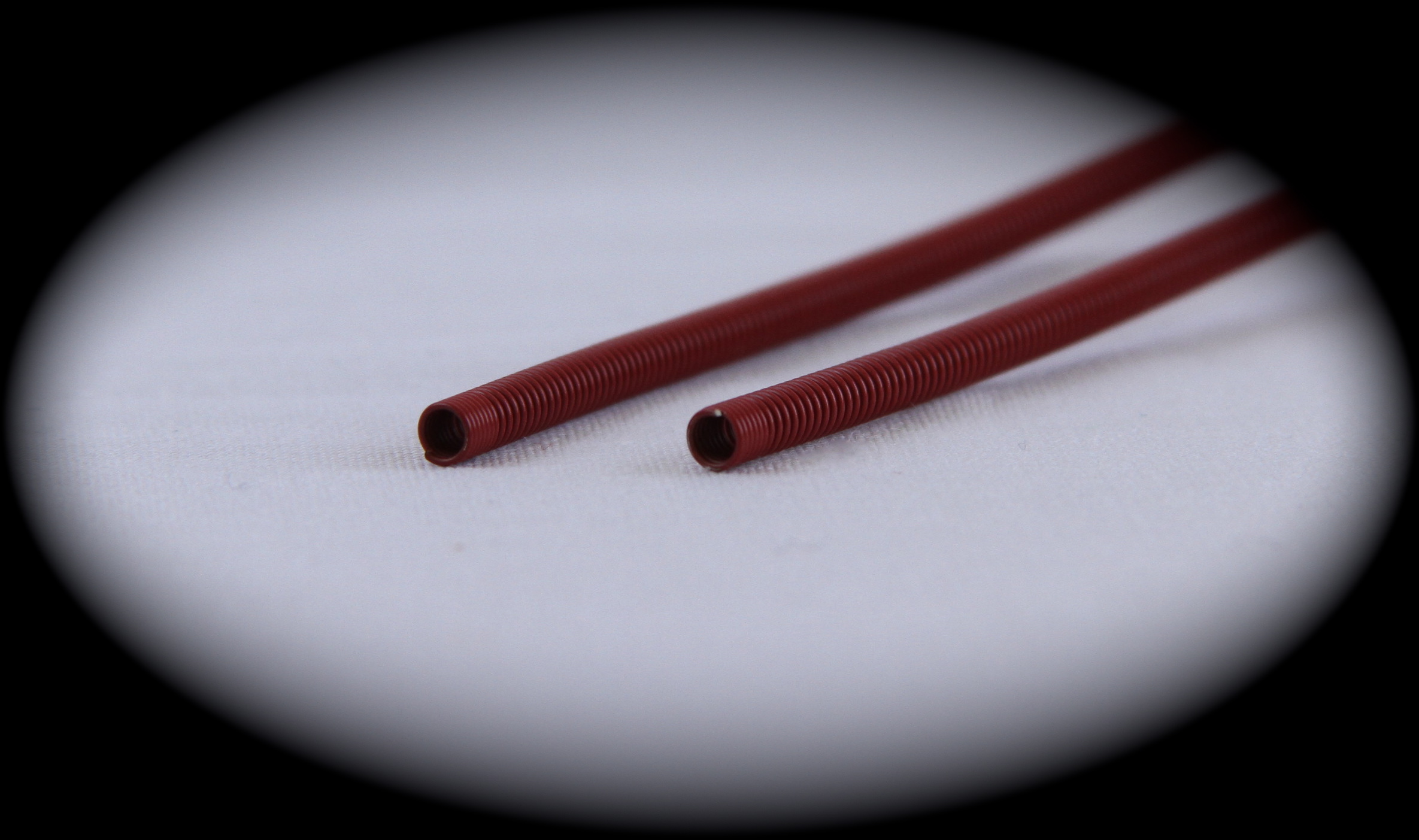

One of the more consistent specifications is ensuring the spring is safely stressed. Therefore, it is essential that the design of the component is accurate and that the part will actually work in the conditions of the end product. It is our job to make sure the parts meet the necessary amount of work cycles.

How do we go about this? It is necessary for us to take a good look at the final application and review the conditions and environment in which the spring will be placed. Proper heating of the part is important for maintaining its memory and ensuring it can withstand and exceed certain conditions. This allows our customers to be confident the parts will succeed in their function.

Our customers consistently call and rely on us to provide them with materials necessary to complete their products and to guide them along the way. We have built trust with our customer base and continue to be their go-to spring and wire form manufacturer.