It’s no surprise that recalls, especially large-scale ones, can be quite costly for big auto manufacturers. The recent string of GM recalls really hammers that point home. Recalls can also show us the dire importance of each component, big and small, in a machine with so many moving parts. It stresses to manufacturers the importance of working with high-quality suppliers who can minimize the risk by delivering well-made parts that are far less likely to cause these kinds of problems.

As many of us know by now, the massive General Motors recall was triggered by faulty ignition switches in millions of vehicles. GM changed the design as a part of cost-saving meaures, and it ended up costing the automaker millions of dollars when its vehicles didn’t work as intended. If it wasn’t for the ignition switch problems, GM could have seen profits comparable to the ones it pulled in the first quarter of last year, around $865 million. Instead GM saw its first quarter profits decline by 86% this year, according to this report. While weakness in some overseas markets played a part in this huge decline, most of that loss can be attributed to the costs associated with this, and more recent, recalls.

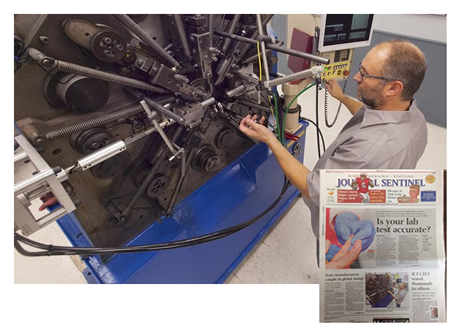

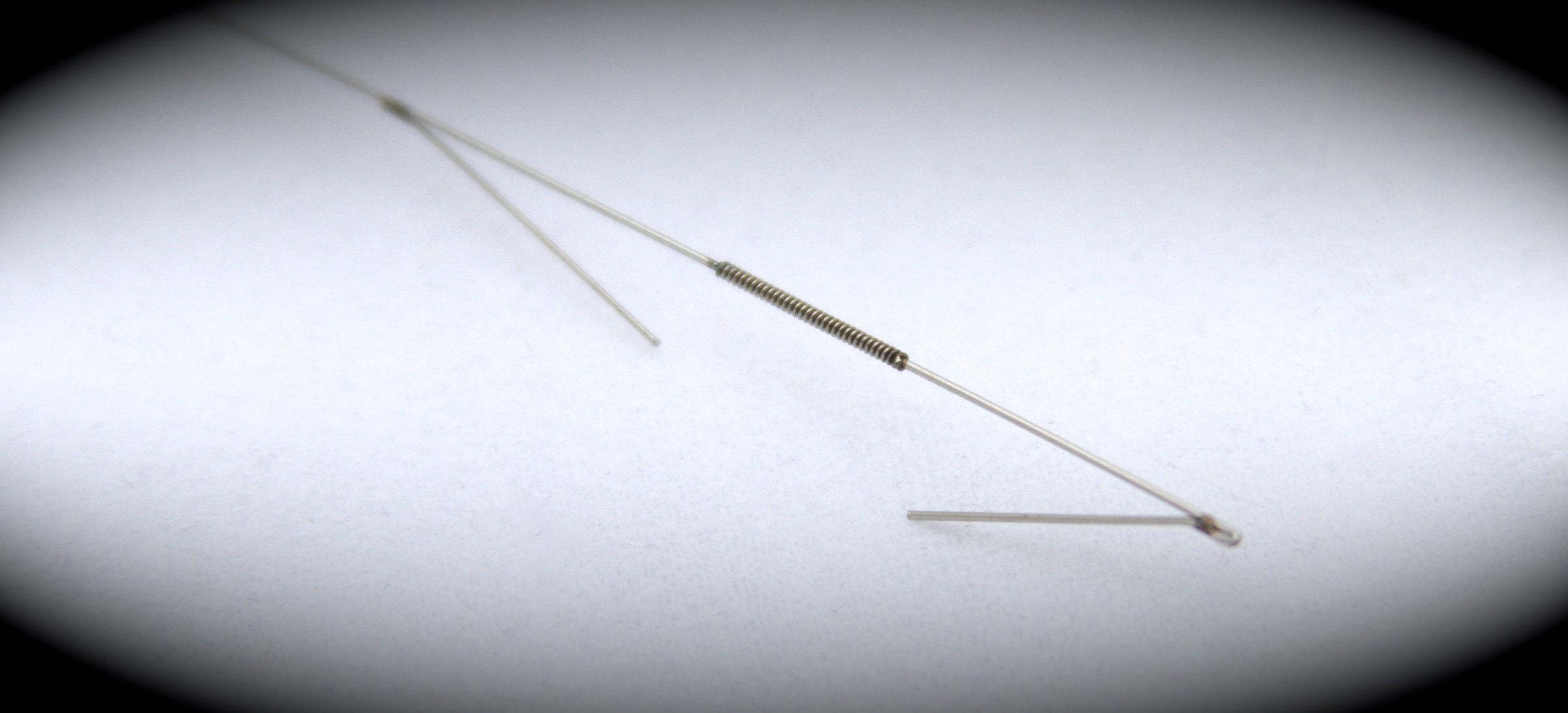

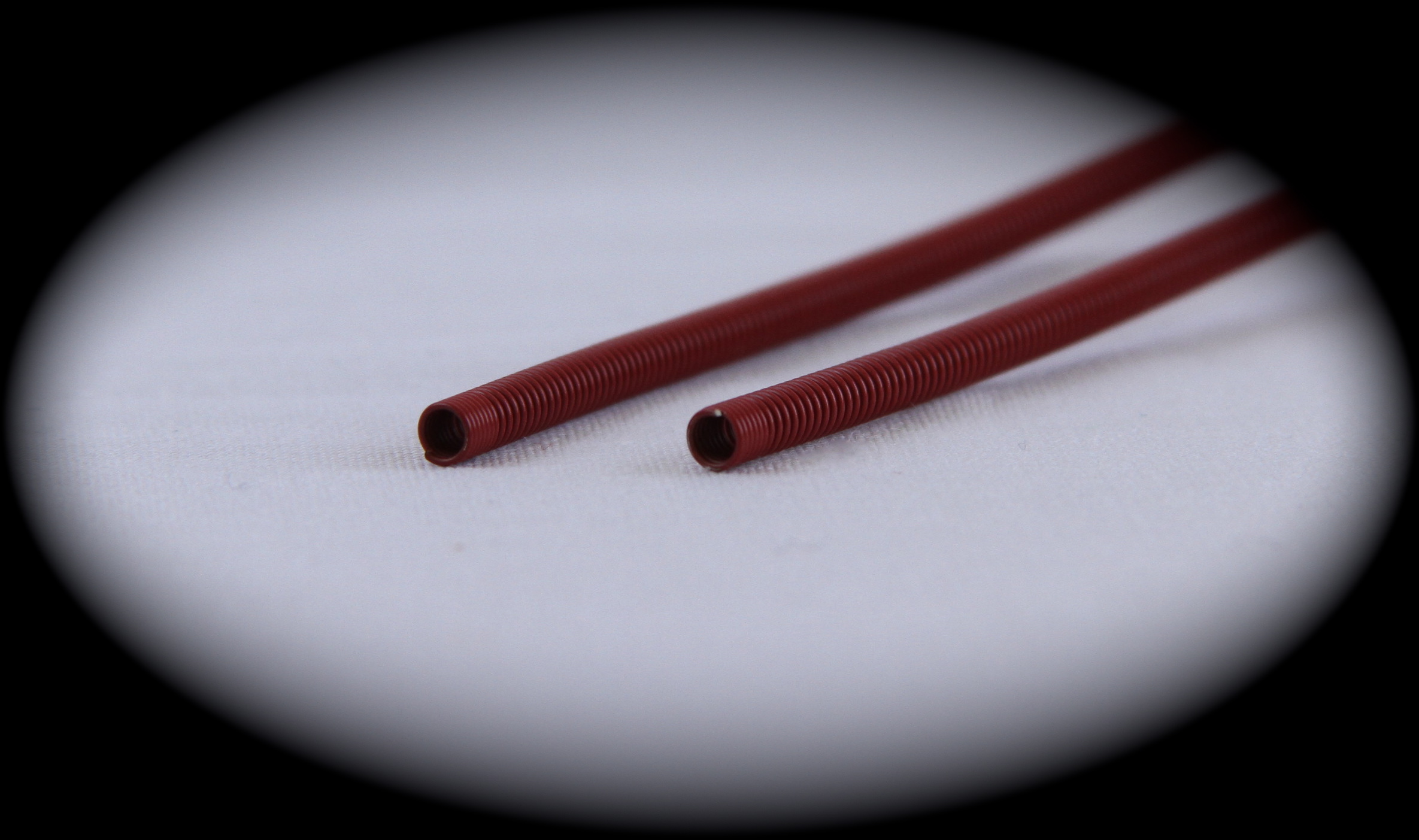

One of the components that was in the switch was a spring. This is why, no matter what component they are producing, a manufacturer needs to set its sights on being a high-quality supplier. Here at Exacto Spring, we may manufacture precision springs and wireforms. Our products are found in anything from cars to appliances, and we take great care to ensure that they’ll keep these complicated devices running smoothly and follow everything that is stated on the control plan, PPAP, prints, etc., No exceptions! Everything we do on the floor has been approved by the customer, and we never stop trying to create better components. Our mission is to be a high-quality supplier because we know how integral each component is to the finished product